Can't see the region you're looking for? You can find a list of our global locations here

Read all instructions before beginning the installation.

All Altro materials, panels, adhesives, sealants and all accessories must be stored between 14°C – 27°C and acclimated to the room which they will be used in at least 24 hours before the installation is to take place. Altro Tegulis panels must be stored on a level flat surface above the ground (risk of condensation on the panels if stored on damp surfaces). Standing the panels against a wall on there side or on uneven surfaces can distort or damage the edges of the panels.

Note: Check adhesive data for specific requirements

All substrates must be smooth, sound, primed and dust-free.

*Plywood must comply to - EN 13986: 2004, BS EN 636: 2003, BS EN 315, BS EN 314-2, Glue bond quality class 3 ‘s’ grade

All surfaces must be smooth, sound, dry, and free of contamination. Check walls for flatness especially at seam location(s), make sure seam area is 100% flat to ensure proper fitting for a successful installation. Priming of dusty and overly absorbent surfaces may be necessary. Existing wall tiles must be cleaned to remove soap residue and contaminants, rinsed with clean water and allowed to dry. Do not use solvents to clean substrate as this could cause a bonding failure. Any loose tiles should be fixed or made sound.

AltroFix W157

Water-based acrylic adhesive is suitable for surfaces in dry, climate controlled areas and may only be used with absorbent surfaces.

AltroFix W139

Two-part polyurethane adhesive suitable for wet areas and for all absorbent and non-absorbent surfaces.

AltroFix W639

Two-part non-hazardous MS Polymer adhesive suitable for wet areas and for all absorbent and non-absorbent surfaces.

Altro Sanitary Sealant

Altro sanitary sealant is a non-toxic, solvent-free, low modulus, multipurpose, one component sealant that is especially formulated for all types of sanitary applications and rooms with high humidity such as bathrooms, kitchens, as well as cold storage areas.

Recommended trowels

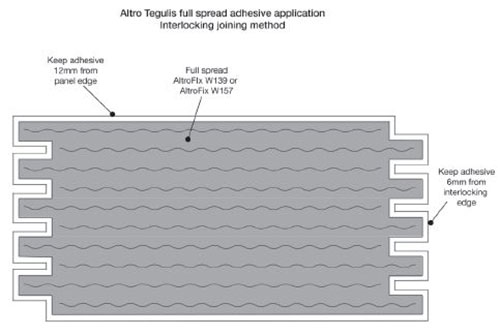

Only use approved adhesives and trowels recommended by Altro. Consult adhesive label for additional information. A 3mm x 3mm square notched trowel is recommended for use with AltroFix W157, a 5mm x 5mm square notched trowel for use with AltroFix W139 and a 4mm x 4mm square notched trowel for use with AltroFix W639.

Note: Altro Tegulis half-lap panels are suitable for both wet and dry environments. AltroFix W139 or AltroFix W639 must be utilised in wet environments regardless of the substrate.

For wet areas only: Internal corners: apply a 2mm bead of Altro sanitary sealant to the substrate vertically on both sides where the sheets meet in the corner before placing the wall sheets. After installation, apply a bead of colour coordinated Altro sanitary sealant in the corner to cover the join.

Note: Altro Tegulis interlocking joining panels are not recommended for wet environments.

Altro Limited, Works Road, Letchworth Garden City, Hertfordshire SG6 1NW. Altro, Altro Whiterock and AltroFix are trademarks of Altro Limited.