Can't see the region you're looking for? You can find a list of our global locations here

Altro products with Altro Easyclean Maxis PUR Technology are manufactured using a different composition to that of standard Altro safety flooring. Due to their makeup, the welding is slightly different to that of standard Altro safety flooring.

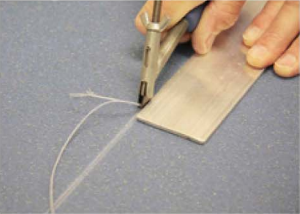

We normally recommend welding at 2 to 3 metres per minute with standard Altro safety flooring, with the gun temperature set at 300-360°C. See Image 1 for necessary tools.

For all Altro safety flooring products incorporating Altro Easyclean Maxis PUR Technology, we would recommend the following points be followed:

NOTE: “Altro Ltd” (“Altro”) endeavours to ensure that advice and information given in Product Data Sheets, Method Statements and Material Safety Data Sheets (all known as Product Literature) is accurate and correct. However, where Altro has no control over the selection of its products for particular applications, it is important that any prospective customer, user or specifier, satisfies him / herself that the product is suitable for the intended application. In this process, due regard should be taken of the nature and composition of the background / base and the ambient conditions both at the time of laying / applying / installing / curing of the material and when the completed work is to be brought into use.

However, as site conditions and the execution of the work are beyond our control, we accept no resultant liability.

Altro’s policy is one of continuous research and development and we reserve the right to update our products and information at any time without prior notice.