Can't see the region you're looking for? You can find a list of our global locations here

Altro is pleased to present our reverse welding service, incorporating our exclusive mechanical process to ensure a strong, reliable, hidden weld.

Keep welds out of sight – and out of mind.

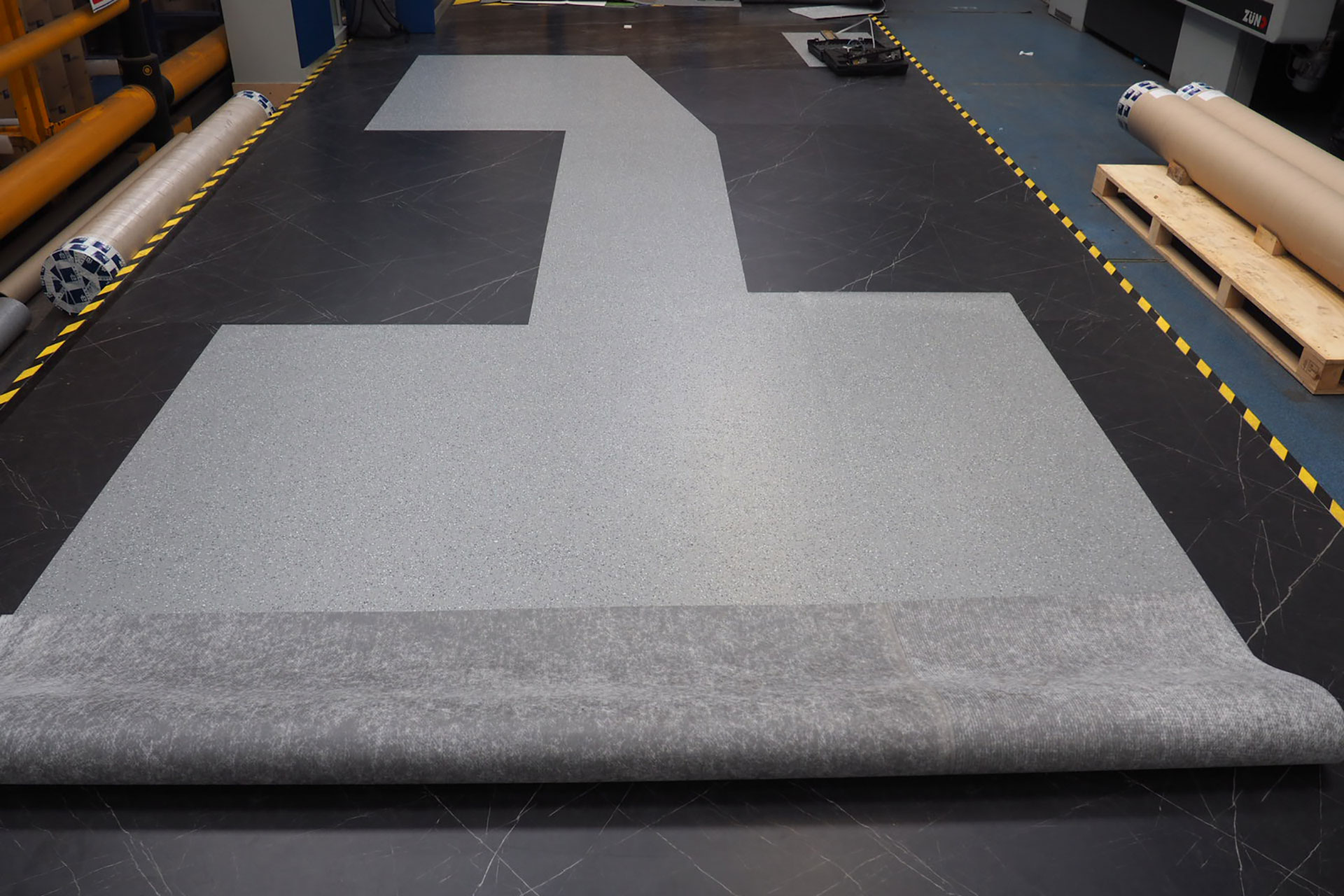

So now you’ve found your perfect flooring design –maybe you’ve chosen an optimal thermal and acoustic solution for your fleet. Next come the decisions. Where to put the weld where it won’t be exposed to heavy traffic, or interrupt your new design? Which weld colour to pick to ensure a good colour match? How to make sure that the best possible weld is achieved? With Altro’s reverse welding service, these challenges are taken care of.

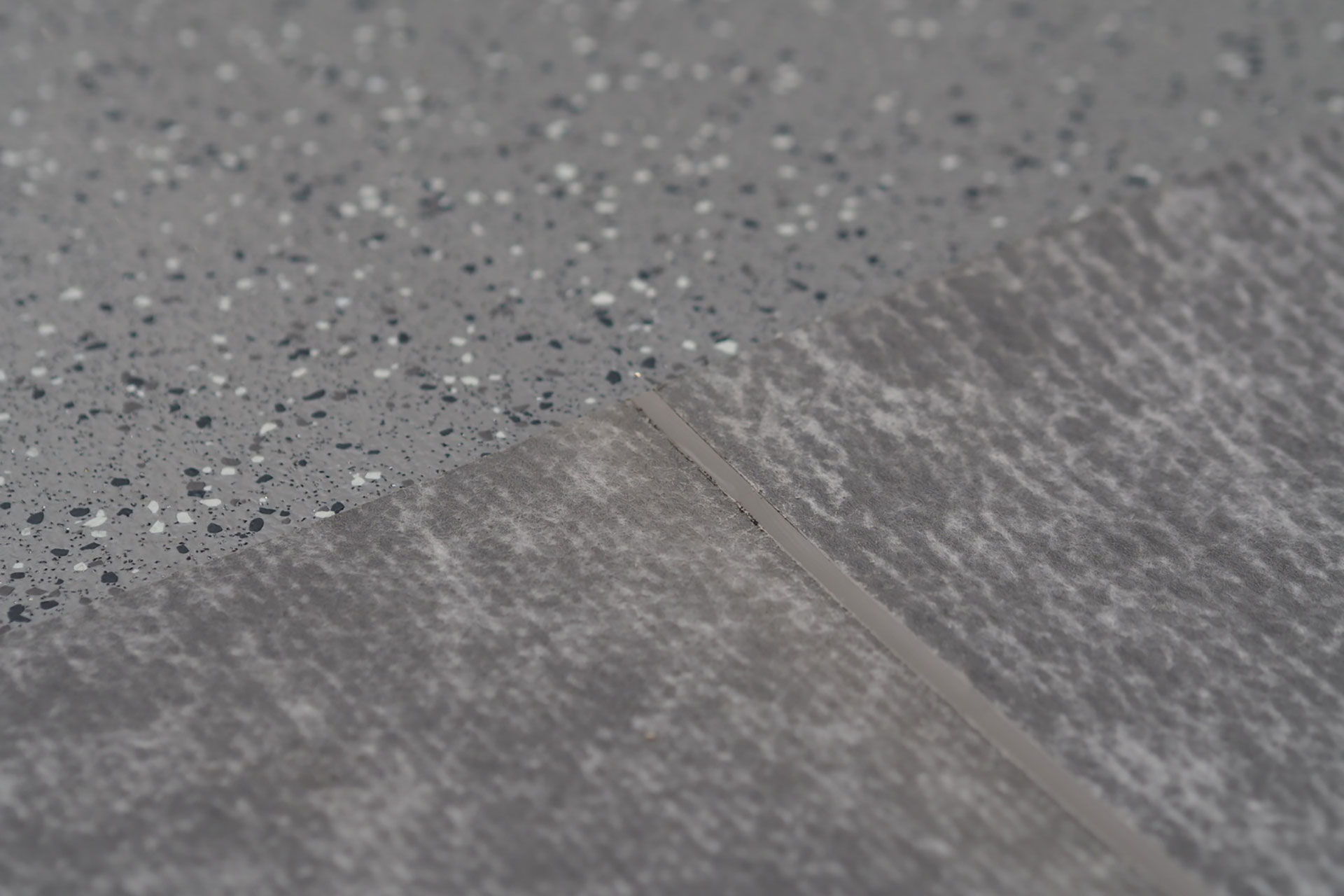

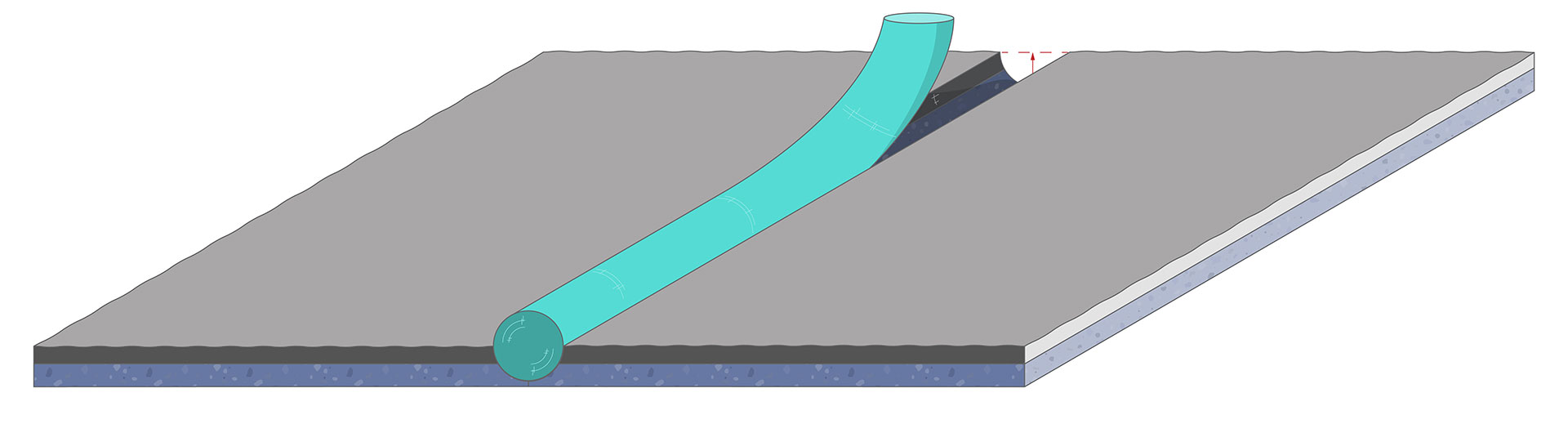

Instead of the traditional weld on the top of the flooring, Altro’s reverse welding process places the weld on the underside, away from potentially damaging foot and wheel traffic. This has the dual benefit of improving both the aesthetics of the flooring design and the longevity of the welds.

Please note: The very nature of this service means that some flooring orders will consist of large rolls which may pose a manual handling risk. Please ensure that extra care is taken to prevent injury when handling and installing reverse welded floors to prevent potential injuries to operatives or damage to the floor itself.

All Altro vinyl and acrylic transport floors are available for our reverse welding service:

| Altro Transflor Chroma EV | Altro Transflor Figura EV | Altro Transflor Meta | Altro Transflor Artis | Altro Transflor Tungsten | Altro Transflor Metris | Altro Transflor Metris Custom | Altro Transflor Sonis |

| ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

With the weld on the underside, the join between two flooring sheets is all but invisible – that means that your carefully chosen design remains uninterrupted. It also means that the weld is protected from foot and wheel traffic, meaning that the risk of failures due to wear are significantly less. Finally, floors welded on the reverse avoid the formation of a common dirt trap which comes with the traditional weld on the top of the floor, giving you an easier ride when it comes to cleaning.

To give you the best possible service for your flooring installation, Altro have developed a new way of reverse welding vinyl floor sheets – and it’s so good, there’s a patent pending on it. This mechanical process ensures that these welds have a consistent groove depth, making for a more reliable weld. We all know that welding is a highly skilled part of laying a floor, so in making the process as machine-led as possible, our reverse welding service eliminates human error, mitigating the risk of weld failures in service.

The welds produced by our exclusive process are rigorously tested with both vacuum (DVS 2225-3) and water testing (EN 13553:2017), so that you can be assured that your subfloor will remain protected throughout the life of the installation. Our reverse welded floors are guaranteed for 3 years.

Like most things in life, our services are better together. Minimise floor cutting time with our pre-cut flooring service, or why not save even more time, as well as extra weight and waste, and order your reverse welded floor with a self-adhesive backing?

Altro’s reverse welding service is compatible with all of our vinyl and acrylic transport floors, but comes into its own with floors where aesthetics are key. The designs of Altro Transflor Wood and Altro Transflor Artis shine best when uninterrupted by weld lines!